Refining the Photomask Manufacturing Process since 1988

Taiwan Mask Corporation, founded in 1988

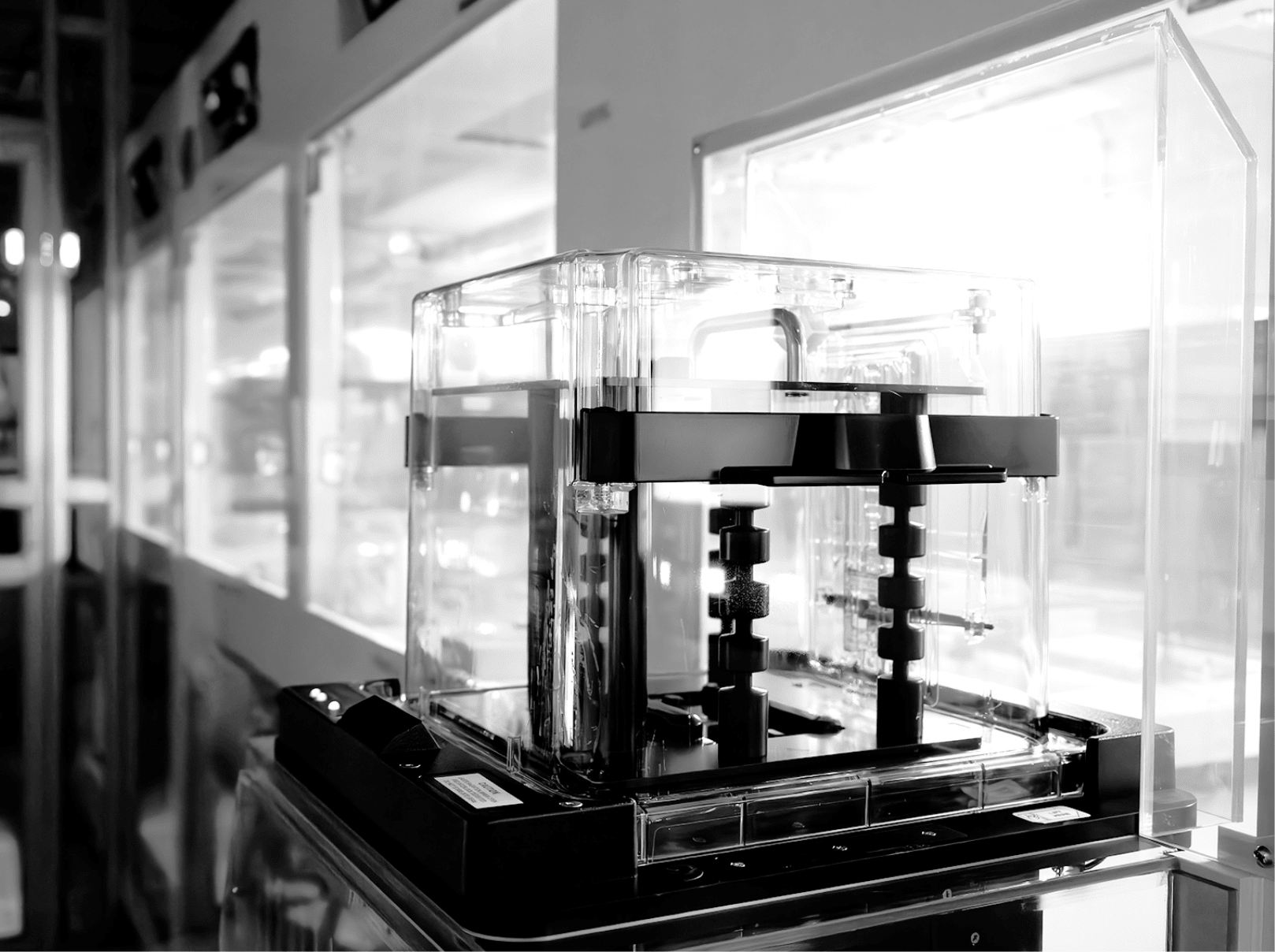

The TMC's journey in the photomask manufacturing process began in 1988. For 35 years we have consistently advanced our technologies and expanded our capacities to meet the ever-growing lithography needs of our customers, with 40nm and 65nm processes the mainstay of our current offerings. Building on an outstanding record of high reliability and robust support, a major business expansion is now underway with the construction of a new fabrication facility in the Tongluo Science Park, as the TMC group looks beyond photomask for a broader range of products and services as part of a long-term strategic plan.

Our continual pursuit of precision in IC manufacturing drives us to meet a wide range of customer standards and account for differing facilities and capabilities by continuously deploying and improving our photolithography enhancement technologies such as OPC (Optical Proximity Correction) and PSM (Phase-Shift Masks) at the 8-inch and 12-inch wafer fabs, enabling us to deliver quality photomasks for the industry-leading chip makers.

Close ties binding the development and applications of the photomask and semiconductor industries

With the semiconductor industry entering a new period of growth fueled by the emergence of 5G, AI, IoT, automotive electronics, high-performance computing and fast-charging infrastructure despite adversities from the COVID-19 pandemic and the China-US trade war, TMC has been able to recognize the opportunity for expansion by increasing production capacity and investing in next-generation tooling and technologies, priming ourselves and our customers for the next phase of growth.

Chairman

David Tu

President

Lidon Chen

Senior Vice President of Finance

Eve Yang

Vice President of Operations

Chaucer Chung

Senior Vice President of Sales

Longsheng Yeou

Senior Vice President

Nester Huang

Vice President

CM Chen